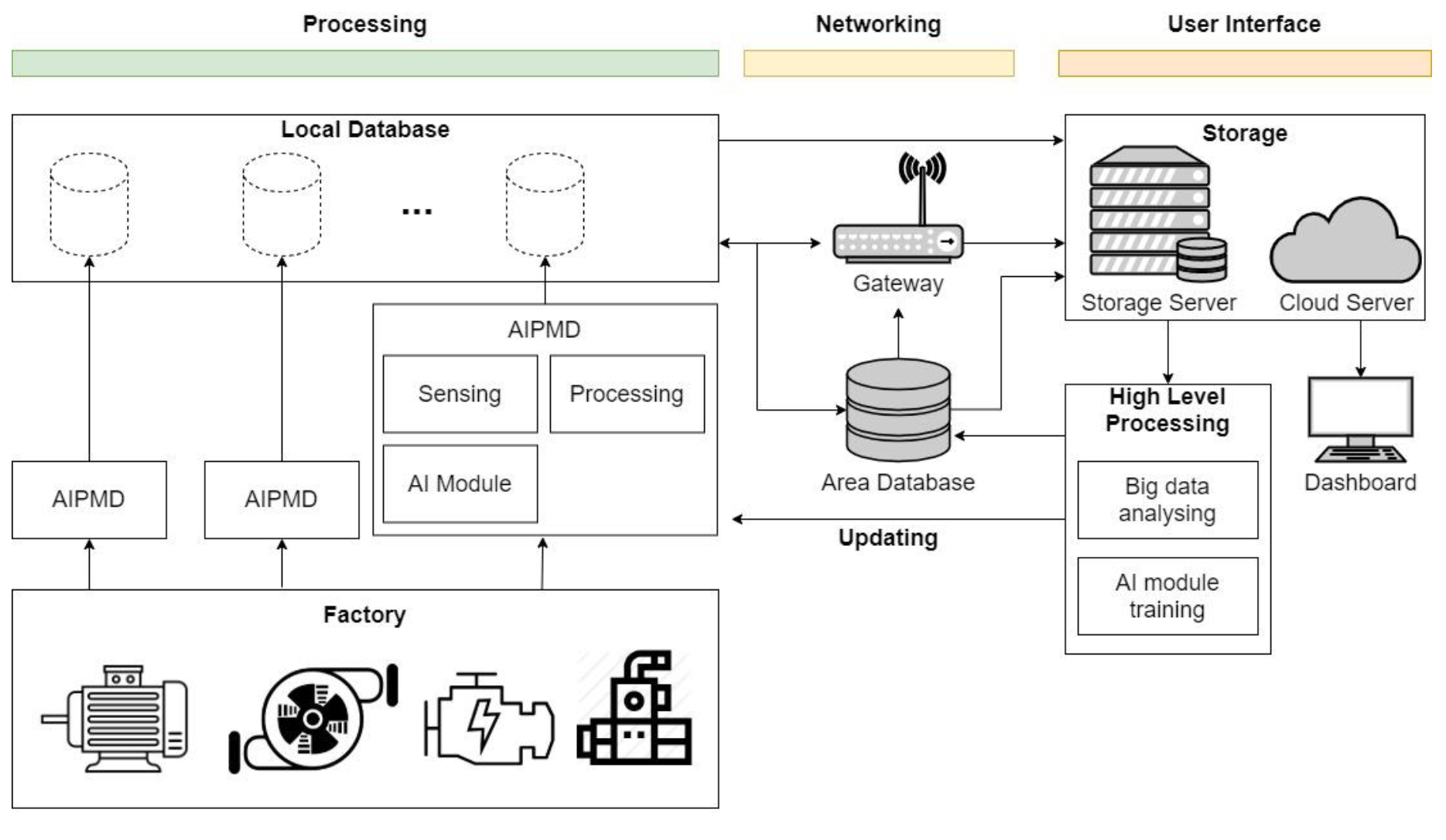

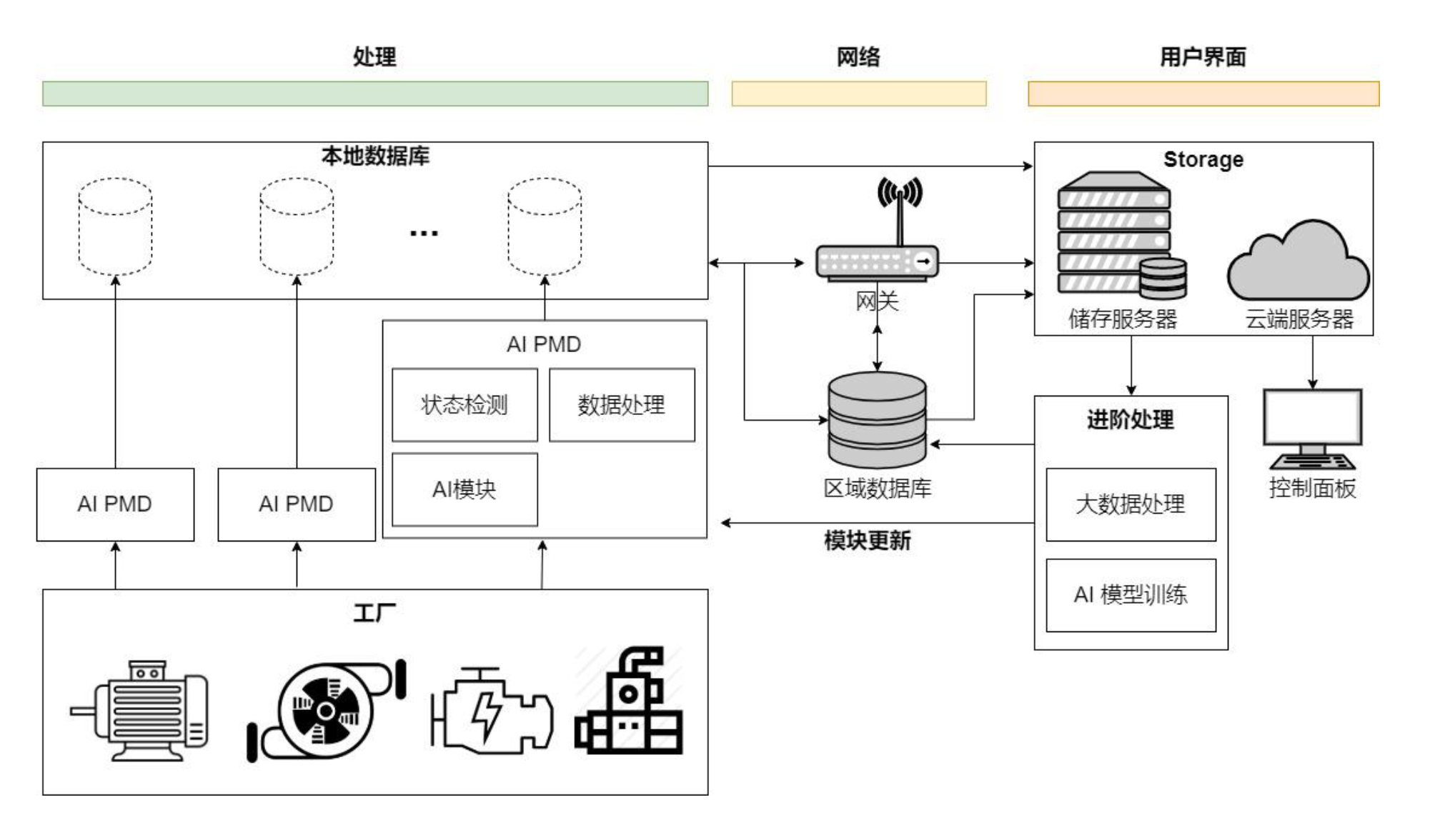

AI PMD An Artificial Intelligent Predictive Maintenance Device

An innovative and latest state of the art device, the iInnovation AI PMD tackles the problem of industrial machines, pumps and motors failing without warning. The PMD is able to give early detection before the machines go into a complete malfunction.

Where there is a need to ensure these machines do not breakdown, the PMD device gives huge savings to factories or companies by detecting/predicting its nearness to complete malfunction. Companies can do a replacement of the machines for off-site repair, thereby saving themselves huge operational losses. In remote places where human constant monitoring of these machines are not practical nor possible, the PMD solution saves large manpower cost as well.

APPLICATIONS

The PMD works on 3 types of Industrial machines: Turbine, Pumps and Heating Ventilation Air Conditioning System (HVAC).

The PMD can be deployed in Power plants where there are turbines used for the generation of electricity. It can be used in large scale steel factories where there are power plants as a by product of steel manufacturing. PMD can also be deployed in Paper factory where there are turbines machineries that needs constant operation.

The next important application area is the pump used in the Oil and Gas industry. Where remote early detection before the failure of the pumps are needed, PMD fulfil this need for Oil and Gas operators where daily human check on the pumps are neither possible nor practical. By predicting the imminent failure of the machine before it fails, actual replacement can be carry out first on the pumps, thus saving companies money by preventing long down time of the pumps.

Similar applications can be used in HVAC system such as those chillers found in offices and industrial buildings. With PMD, instead of scheduled maintenance, maintenance can be done according to the actual state of the HVAC system, thus giving the stake holders savings in maintenance cost.